TYRANNOSAURUS® Shredders and BioCrushers are the core of our expertise. They are the outcome of long experience in material handling combined with outstanding engineering skills. TYRANNOSAURUS® Shredders and BioCrushers represent smart technology, raw power and excellent availability with high capacity.

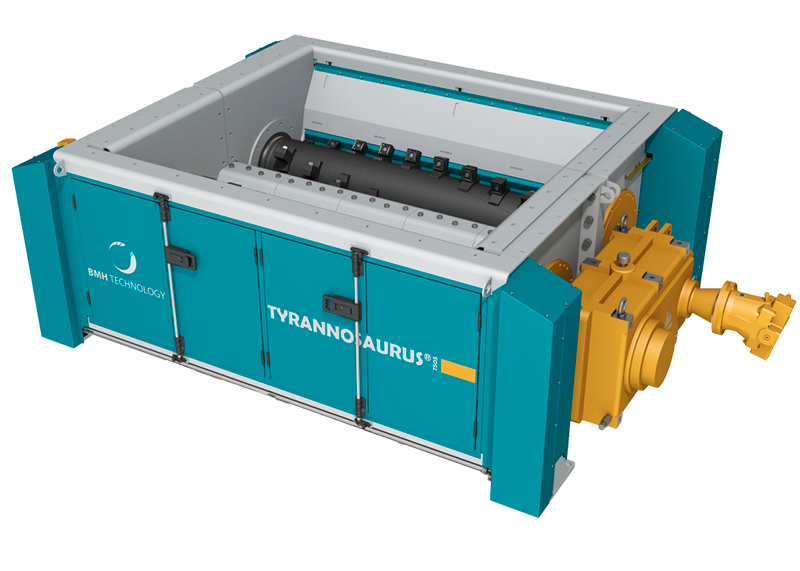

TYRANNOSAURUS® PreShredder

As the quantity of wet organics is usually high in MSW (Municipal Solid Waste), the waste should be presorted before the actual SRF/RDF production process. Incorporating a TYRANNOSAURUS® PreShredder into the process will increase the capacity of the entire production line and further improve the quality of the end product.

TYRANNOSAURUS® PreShredders are an ideal solution for rough shredding. They are especially designed to open plastic bags and prepare waste for organics separation.

The TYRANNOSAURUS® PreShredder is a two-rotor, slow-running waste reducer of extremely robust construction, specially designed for industrial purposes at a high capacity. The machine has a large number of features to ensure reliable and economic operation, for example easily exchangeable knives.

The preshredder reduces the material to the size of < 300 mm enabling the subsequent separation process to work optimally.

TYRANNOSAURUS® PreShredders are also available for primary shredding of waste in grate fired incinerators.

TYRANNOSAURUS® 9900 Shredders

The TYRANNOSAURUS® 9900 Shredders for MSW (Municipal Solid Waste) and ICW (Industrial & Commercial Waste) are of extremely robust construction and designed for heavy-duty industrial purposes. They represent most advanced technology and strongest design in the market.

TYRANNOSAURUS® 9900 Shredders have a long list of features to ensure reliable and economic operation

- Heavy-duty frame.

- Rotor made of forged steel.

- Heavy-duty bearings.

- Fully hydraulic heavy-duty drive system at both ends of the rotor. The blockage free drive system provides maximum torque at all speeds. The speed of the rotor is adjustable, typically from 50 to 100 rpm.

- Mechanical couplings are provided between the rotor and the hydraulic motors to protect the motors from radial and axial shocks.

- Separate industrial hydraulic power pack, including leakage oil pan, cavitation protection of the main pumps, level detectors, temperature detectors, filtering systems, shut-off valves, heavy-duty air cooling and oil preheating.

- Each 800 mm counter-knife section has hydraulically-assisted ZeroGap® adjustment to ensure high capacity even with worn knives.

- Central lubrication system.

- The counter knives are of the same type as the rotor knives and can be individually replaced and turned to new cutting edge.

The MIPS® (Massive Impact Protection System) feature protects the knives and screens from severe damages if non shreddable materials enter the machine. When a solid object exceeding the boundary limits hits any of the counter knife assemblies, this counter knife section and the opposite screen section open. The rotor is simultaneously stopped by setting the hydraulic motors in the brake mode. After that the ram will push the rejected object out of the machine.

- The rejected object and a portion of unshredded waste stream coming out at the same time are taken out of the process to a reject bunker.

- Automation of the machine by means of Siemens control logic with large monitor.

- Maintenance control panels.

- As an option, the equipment can be delivered with a remote control unit that can be located for example in the front loader cabin.

TYRANNOSAURUS® 8800 Shredders

TYRANNOSAURUS® 8800 Shredders are designed for shredding MSW (Municipal Solid Waste). They are high performance shredders with emphasis on superior availability, high capacities and carefree operation.

HIGH PERFORMANCE

TYRANNOSAURUS® 8800 Shredders provide excellent shredding capacity and output quality. Hydraulic Power Transmission ensures high operational hours with maximal torque for optimal shredding performance. Changeable screens ensure desired particle size in a single shredding phase.

SUPERIOR AVAILABILITY

The operation is highly automated. Big doors and patented inward-opening hatch system make it fast, easy, clean, and safe to access the shredder, if necessary. Robust construction makes the shredders withstand impurities such as rocks, cement, metals, etc. Big doors and hatches make it easy, safe and fast to remove non-shreddable impurities from the shredder.

Main advantages

- ideal for unsorted MSW,

- works in demanding conditions and with high moisture materials,

- easily exchangeable knives and screens,

- low operating and maintenance cost,

- highest availability hours – minimum maintenance stops,

- high capacity, even output quality and

- intelligent control system for optimal shredding.

INTELLIGENT SHREDDING

TYRANNOSAURUS® 1200 Fine Shredders

TYRANNOSAURUS® Fine Shredders are used for reducing the particle size of SRF/RDF down to even less than 25 mm. This will increase the combustibility of the fuel.

TYRANNOSAURUS® Fine Shredders are of heavy duty construction and designed for industrial use. They have low operating and maintenance costs and function flawlessly together with the entire process.

The shredder has several features, which ensure economical and reliable operation:

- robust frame,

- heavy duty bearings,

- advanced logical control system,

- adjustable drive by means of frequency converter and

- hydraulically supported counter knives.

TYRANNOSAURUS® 9000 BioCrushers

The low-speed TYRANNOSAURUS® 9000 BioCrusher is a safe, economical and efficient way for crushing e.g. wood-based residues, bales, pallets or stumps as well as cardboard, paper rolls and other packaging material. Low-speed crushing means less dusting and smaller amount of fines. It decreases the risk of sparks, fire and dust explosions as well as the likelihood to face damages caused by metal and stones.

The heavy-duty TYRANNOSAURUS® BioCrusher produces even capacity with high availability and low operating costs. It has a spacious in-feed chute located above the crusher to receive material either from a preceding

conveyor or directly from a vehicle, even a whole truckload at a time. The rotor is armed with teeth, made of special steel, that can be turned and are easy to change. The rotor’s running is reversible and crushing takes place in both directions.

TYRANNOSAURUS® 9000 BioCrushers are available with one-rotor or two-rotor design and various drive alternatives to fit different capacity and in-feed material requirements.

TYRANNOSAURUS® 6500 BioCrushers

TYRANNOSAURUS® 6500 series BioCrushers are suitable for secondary crushing of screened oversize material to ensure suitable quality of the end product. The crusher is designed to minimize overheating and sparking. Turnable teeth with screw fastening enable fast and easy maintenance.

TYRANNOSAURUS® BioCrushers are available with one-rotor or two-rotor design and various drive alternatives to fit different capacity and in-feed material requirements.